WORK

Crafted in Japan with pride since 2008.

Prepreg (carbon sheet) which is material of carbon fishing rod have to be kept fresh.

It is kept in fridge and have to be cut in the room where temperature and humidity is controlled.

By cutting prepreg promptly and accurately, it will be related to manage quality of this manufacturing.

There are so many kind of prepreg with various characteristics and craftsman combine these materials effectively to be able to build so many different kind of fishing rods.

Person who cut these materials have to care about not only thickness and stiffness of prepreg but also what kind of resin have been penetrated into the carbon sheet.

We believe that craftsman supposed to be needed knowledge of material and experiences as professional.

Wind carbon material around mandrel…

sounds simple but extremely delicate.

Prepreg which have been cut is wound around mandrel in various way and combinations.

There are many different kind of mandrel to cover variety of taper and length of fishing rod that designer wish to build.

Put prepreg on the edge of mandrel by hand and roll it up with machine while keep putting pressure on it.

This manufacturing is required lots of experiences to avoid risk of failure of products.

Because even a little distortion of prepreg will be cause of breakage of blanks.

Wound very carefully then it will be set into oven to make it fine blank as fishing rod.

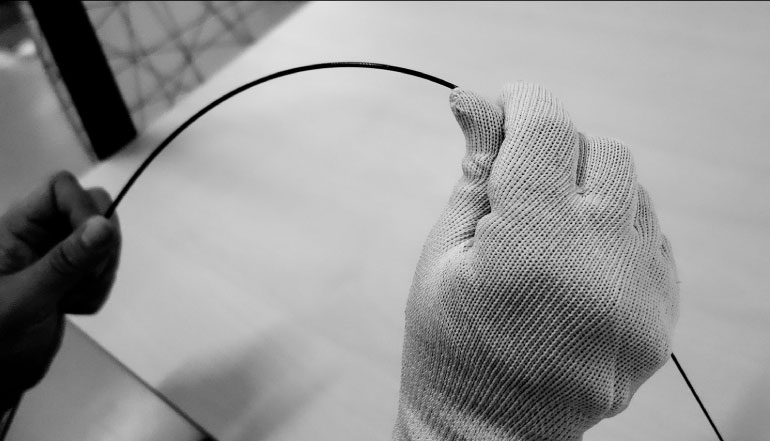

Strength of blanks…..it is depend on this inspection.

Our blanks that have been come out from oven are inspected by hands of specialized staff.

Even though these blanks have been manufactured by skilled craftsman, it can’t be 100% sure as long as depending on human’s hands.

Fishing rod supposed to be required high reliability as mainstay tool of fishing.

We will never ever stop inspecting to make all customer who actually fish with our fishing rod satisfy.

This is why specialized staff inspect blanks one by one.

Blank will be tuned into fishing rod through many steps.

Blanks that is passed inspection are going to be cut, polished and painted.

And after these processes, parts of grip are going to be adhered, guides are going to be fixed with thread.

Blanks will be turned into fishing rod little by little through many steps many times.

Fishing rods are industrial products that are

manufactured by craftsman.

Using Prepreg as known as advanced industrial material we believe that fishing rod is handicraft product that have to be manufactured by hands of craftsman.

Only simple movement such as “Rolling up” and “turning” are relied on the machine…

Many specialized staff is working on their own section with responsibility…

Products which are on the production line will be inspected strictly one by one…

Manufacture fishing rod that will be relied on truly…This is what we think all the time.

We believe that it is the only way to build relationship of trust for a long time with anglers who have chosen us.

This is why we are going to keep manufacturing fishing rod here in JAPAN.